Thermtip®Disposable Thermocouples

Thermtip® is a disposable temperature sensor for instant measurement of molten metal temperature. The sensor is a noble metal thermocouple of Type B, R or S with the thermo-elements conforming to Class-II, ITS-90 calibration standard. Type C and G are available on special request. The sensor is fixed to one end of a long paperboard tube in order to allow for easy immersion into molten metal. The length of the paperboard tube is customized according to the requirements of the customer. This probe is fixed to a lance to dip into the molten metal and the signal is transmitted by special compensation cables to the Thermtip® Instrument in order to accurately measure the temperature of the molten metal.

Use of Thermtip® allows steel makers to accurately and immediately measure the temperature of the molten steel/hot metal which in turn enables better process control. More information is available in the catalog below.

Acucast® Continuous Temperature Sensors

Acucast® is a continuous temperature measurement probe intended for use in continuous casting tundishes. It is fixed to the Tundish through the side wall or the bottom wall and measures the liquid metal casting temperature throughout the casting sequence. In order to fix this probe into Tundish wall, a refractory well-block is fixed in the Tundish refractory and the probe is inserted through the guide hole in the well block and retained in place with a special mortar. Continuous measurement of Tundish temperature offers many advantages. Some of these advantages are:

| 1 | Precise control of casting speed in Tundish thus allowing for better efficiency |

| 2 | Preventing break-outs due to availability of real-time casting temperature |

| 3 | Operational efficiency due to option to operate casters at lower superheat |

| 4 | Higher metal recovery due to better knowledge of slag-metal interface in Caster |

| 5 | Safer operating environment since human involvement for dipping sensors into the metal is avoided |

Acutap® BOF Drop Sensor

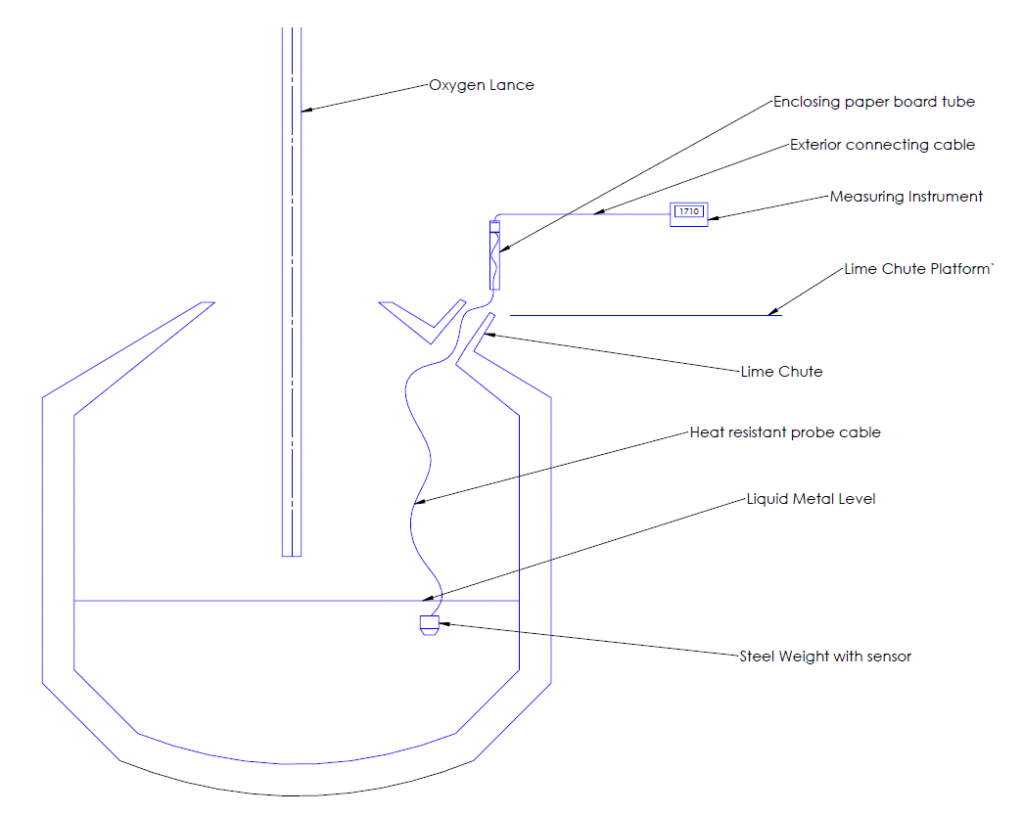

Acutap® is a drop sensor specifically designed for measurement of temperature and oxygen in the BOF. Typically, in order to measure the temperature, the converter must be tilted and a sensor then dipped manually into the molten metal in order to measure the parameters. By using Acutap®, these steps can be avoided and at the push of a button, a probe is “dropped” into the converter while the converter is still vertical. The probe consists of a thermocouple fixed onto a metal weight and connected to a measuring instrument by a long length of coiled cable. When the probe head is dropped into the metal, the weight carries it downward and into the metal and the long cable uncoils while transmitting the sensor signal to the measuring instrument. Acutap® is an alternative to sublance measurements for existing converter shops where logistical and other operational reasons prevent the use of sublance sensors.

By avoiding the need to tilt the converter for taking a measurement, significant savings in time can be realized in the BOF process. These savings in time translate to higher productivity. Additionally, lower metal losses are also realized as the need for de-slagging (and the consequent loss of some metal along with the slag) are avoided for taking a measurement. Acutap® probes are available for both temperature and oxygen measurement. A schematic representation of the system is as below: